Prati Aero

Activity description

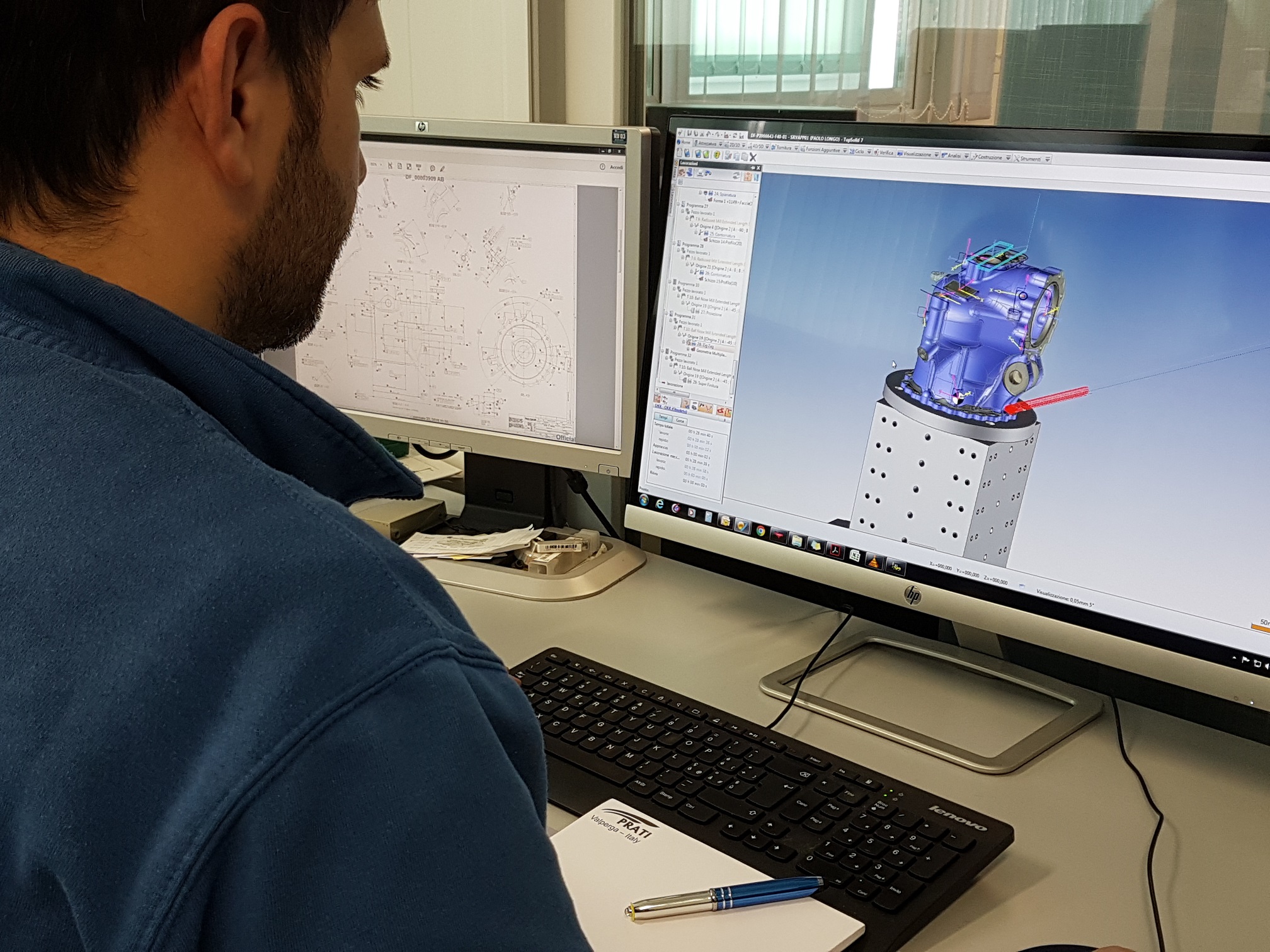

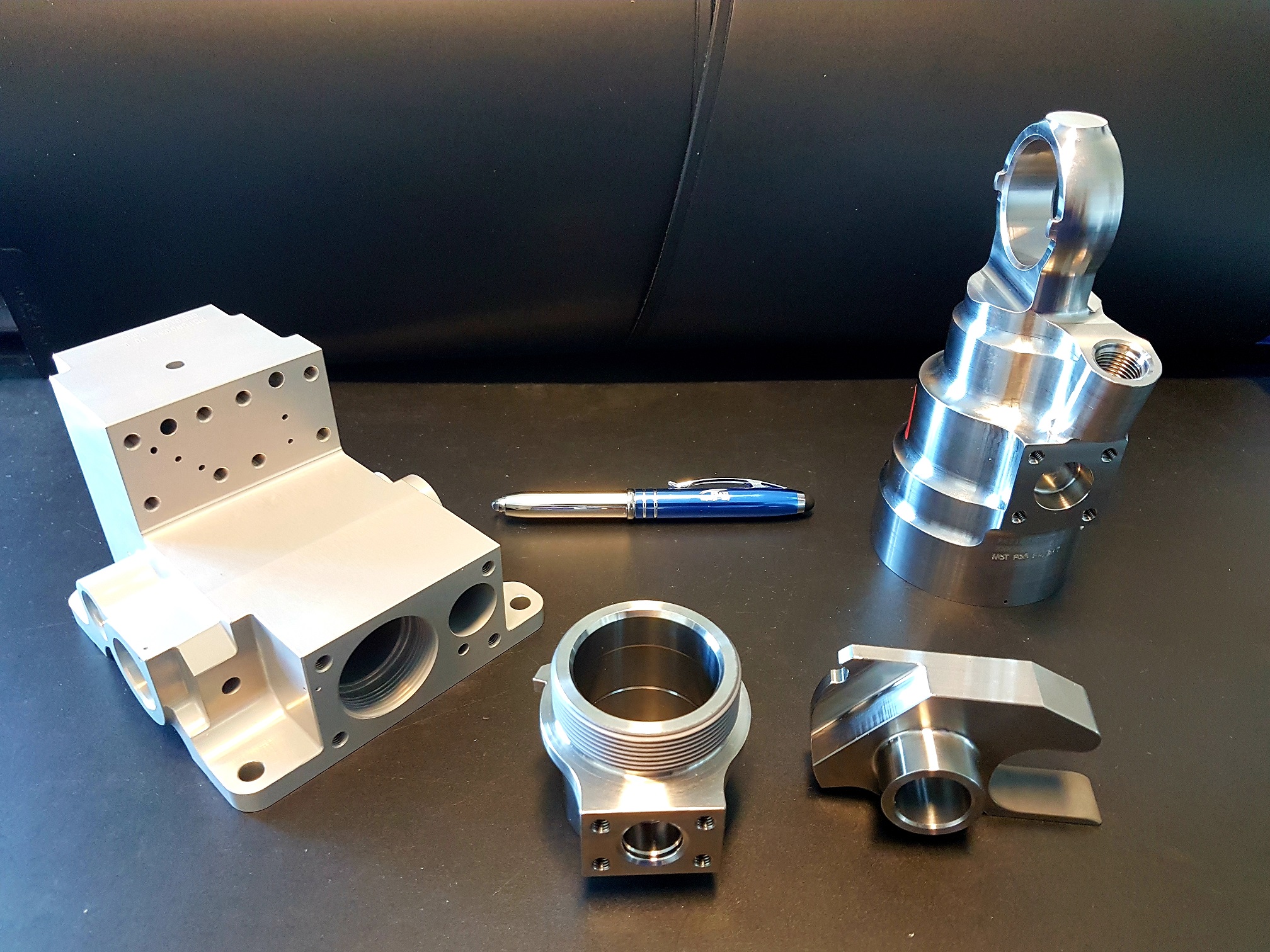

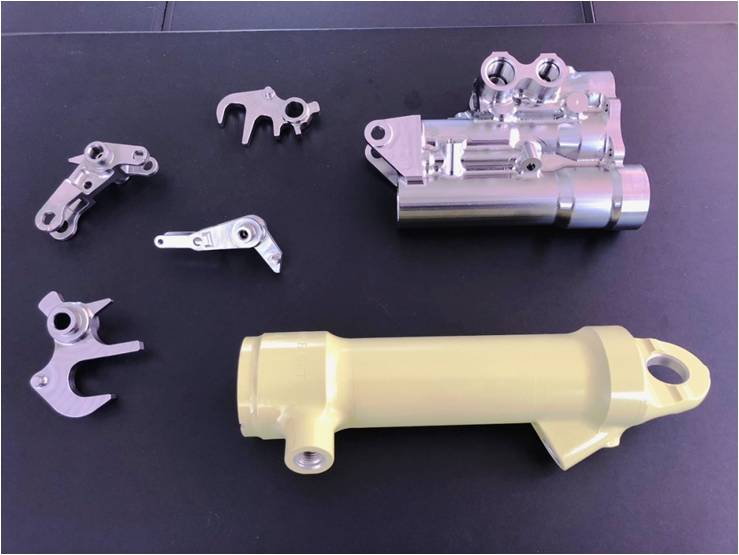

We are supply some of the world’s largest OEM’s with complex built-to-print machining parts and assemblies. Strong attitude to produce prototypes and release certified product with optimized short run time supported by PPAP associated analysis. Planning and ops processes supported by ERP systems with MRP II. 3D modeling CAD/CAM software, precision CNC machining, CMM measuring and testing capabilities are interconnected with the ERP systems. Special processes procured through a network of NADCAP accredited suppliers approved by final Customers. Visual and Dimensional inspection based on state-of-the art tooling. Testing capabilities include pressure and flow testing performed on test stand designed to purpose. Mgmt system qualified EN9001/EN9100. Product machined from bars, plates, castings or forgings apply to: 1) Engine transmission/Lubrication: Gear-box housing, Covers/Adapters, Oil pumps and tanks, Filters, Manifolds, Air/oil separator, Filler necks, Valves 2) Flight Controls, Landing Gear and Nacelle: Actuators, Rod Ends, Cylinders, Locking/Release devices 3) Hydraulic: Power Control Module, Filters, Hydraulic Valves, Reservoirs

Other key sectors

Aerospace

.jpg)

.jpg)